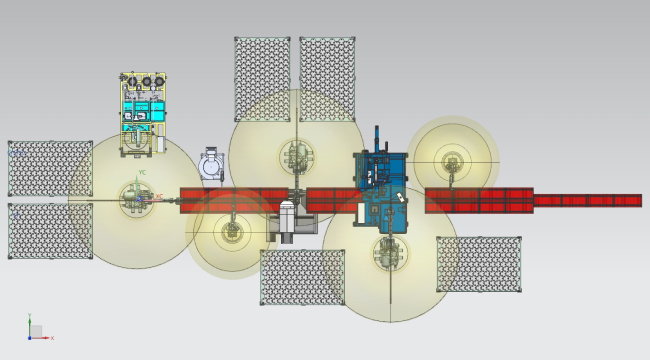

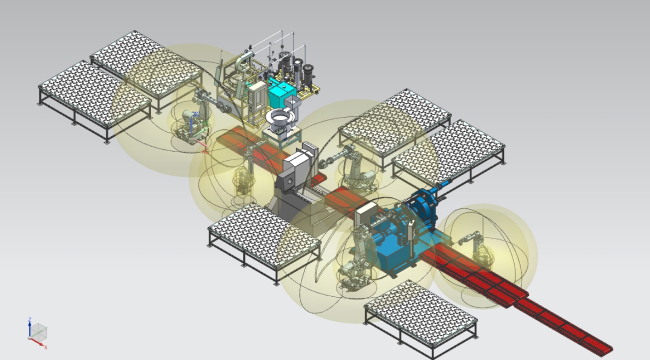

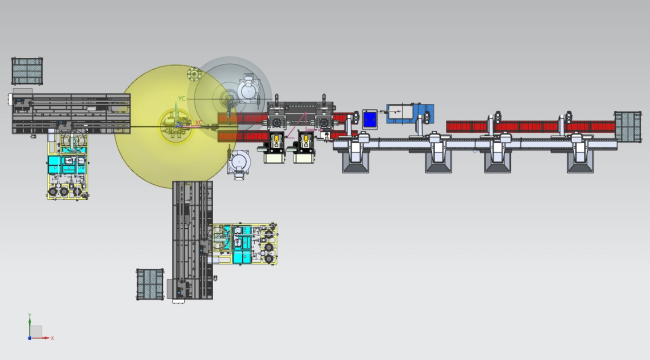

| Automation line of painting/assembly |

- |

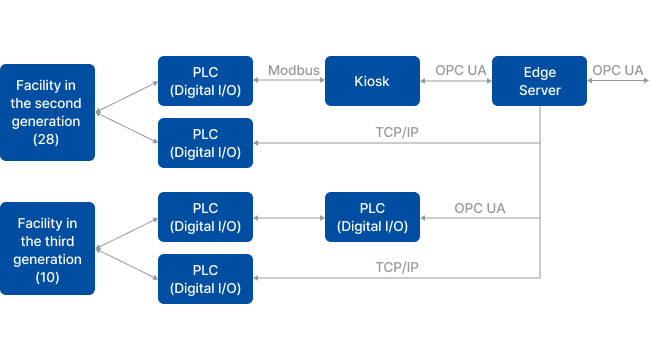

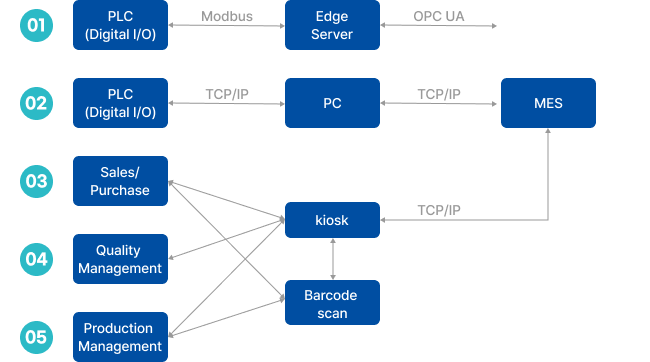

- Operation/Non-operation of the Line, Count, Speed of Chain Rotation, Detection of Heterogeneity, Gripper Pressure, Pressure on the washing nozzle, Conveyor motor load rate, etc

- Amount of Electricity

|

Automation |

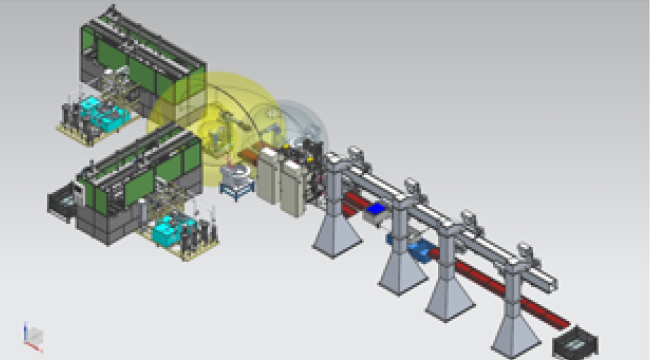

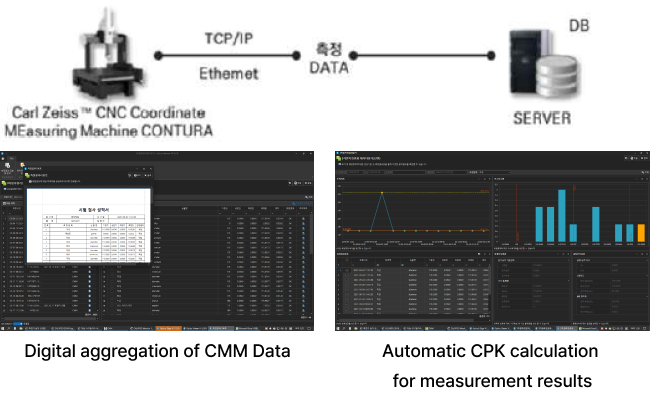

| 3D measuring instrument |

- |

|

Automation |

| Sales/purchase Management |

Bar Code Scan, Input Data |

- Shipping Products

- Stock/return

|

Semi-automatic |

| Quality Management |

Input Data |

- Inspection results, inspection reports, etc

|

Semi-automatic |

| Production Management |

Bar Code Scan, Input Data |

- Registering workers, Operation/Non-operation by facility, Production items by facility, Production Performance, LOT management, etc

|

Semi-automatic |