Leading Model for Heavy Equipment and

Parts Industry with Diverse Types of Small Quantity

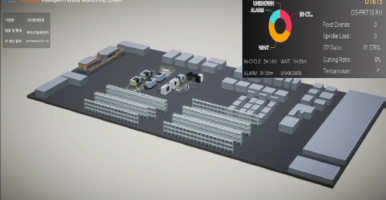

(Digital Twin K- Smart Lighthouse Factory)

Open Innovation Sharing Center

-

People

-

Data

-

AI Collaboration

Management strategy to satisfy customers' needs

(3D Design / Optimization of manufacturing process + Maximum productivity + Intelligent quality / Establishment of ESG management system)

- Traditional manufacturing techniques

- Based on Toyota System JIT

- Product Design

- Tool Management

- Flexible production management

- Human resources management (Fair education/Retraining)

- Advanced techniques of manufacturing factory management

- Lean maunfacturing

- Manufacturing Execution System (MES)

- Overall Equipment Effectiveness (OEE)

- Product Lifecycle Manugement (PLM)

- Factory Energy Management System(FEMS)

- Advanced Smart Factory

- Service

- AI

- 5G Cloud

- Digital Twin

- AAS * KAMP **

- APS ***

- * AAS : Asset Administration Shell

- * KAMP : Korea AI Manufacturing Platform

- * APS : Advanced Planning and Scheduling

-

Quality

Quality first policy

-

Technology

Improving competitiveness

-

People

Social Contribution

-

Environment

Nature-friendly management

-

Safety

Safe working environment

-

Ethics

Robust corporate culture